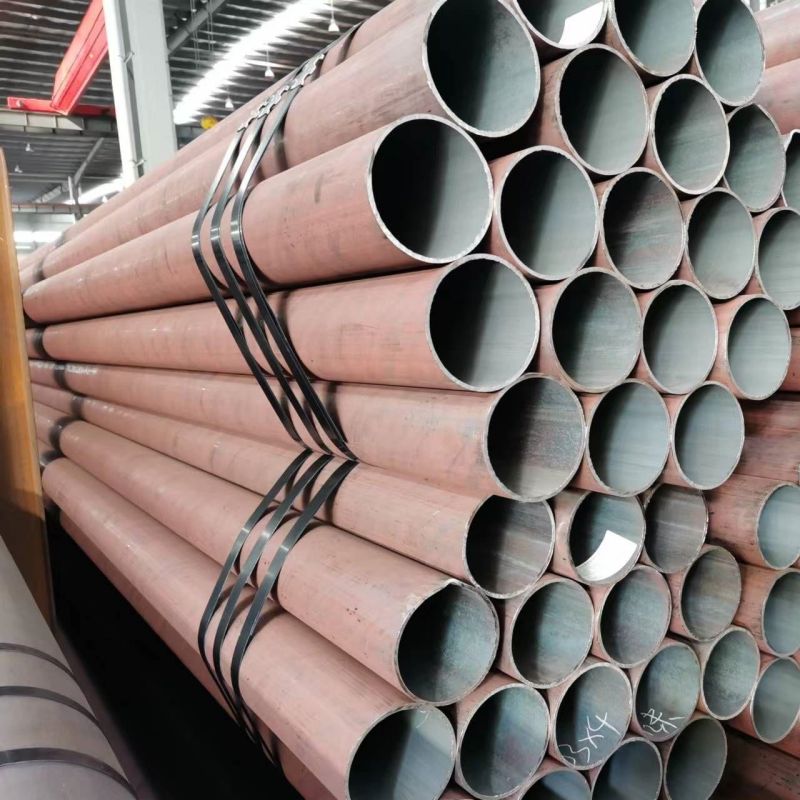

DIN 17175 an ƙera shi don dalilai masu ɗagaɗaɗɗen zafin jiki, ANSON yana ba da ma'aunin ƙarfe: St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910.DIN 17175 bututun ƙarfe marasa ƙarfi ana amfani da su sosai a cikin na'urorin musayar zafi.Wannan ƙananan gami yana da ƙarin ƙarin molybdenum da manganese a ciki.Bayan amfani da shi a tsarin tukunyar jirgi, yana da amfani ga aikace-aikace a cikin masana'antar mai, iskar gas da sinadarai.Gabaɗaya, waɗannan masana'antu suna amfani da masu musayar zafi, a matsayin hanyar canja wurin zafi tsakanin mafita biyu ko fiye.Ana yin bututun da ke ƙarƙashin DIN 17175 daga carbon da ƙananan ƙarfe na ƙarfe waɗanda ke da juriya ga lodi a ƙarƙashin matsanancin matsin lamba da yanayin zafi.Ana amfani da su don gina kayan aikin injiniya na wutar lantarki kamar: tukunyar jirgi, dumama, murhu, dumama, bututun musayar zafi.

DIN 17175 ana amfani da bututun ƙarfe marasa ƙarfi don shigarwar tukunyar jirgi, bututun mai ƙarfi da ginin tanki da injuna na musamman don duka zafin jiki da na'urori masu ƙarfi (Sama da 450 ° babban zafin jiki).ANSON gogaggen tukunyar jirgi ne da mai siyar da bututun ƙarfe wanda zai iya ba ku DIN 17175 bututun ƙarfe na kowane nau'i da kewayon girma.