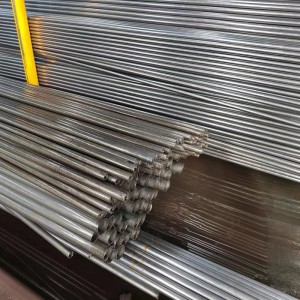

40CrMo 42CrMo 42CrMo4 Alloy Steel Pipes/Tubes

Short Description:

42CrMo alloy seamless pipe is an ultra-high strength steel with high strength and toughness, good hardenability, no obvious tempering brittleness, and small deformation during quenching. After quenching and tempering, 42CrMo alloy seamless pipe has high fatigue limit and multi impact resistance, good impact toughness at low temperature, and high creep strength and endurance strength at high temperature. Surface quenching after quenching and tempering is usually used as the heat treatment scheme for 42CrMo alloy seamless pipes.